Cutting systems and software from the same source.

An intelligent combination.

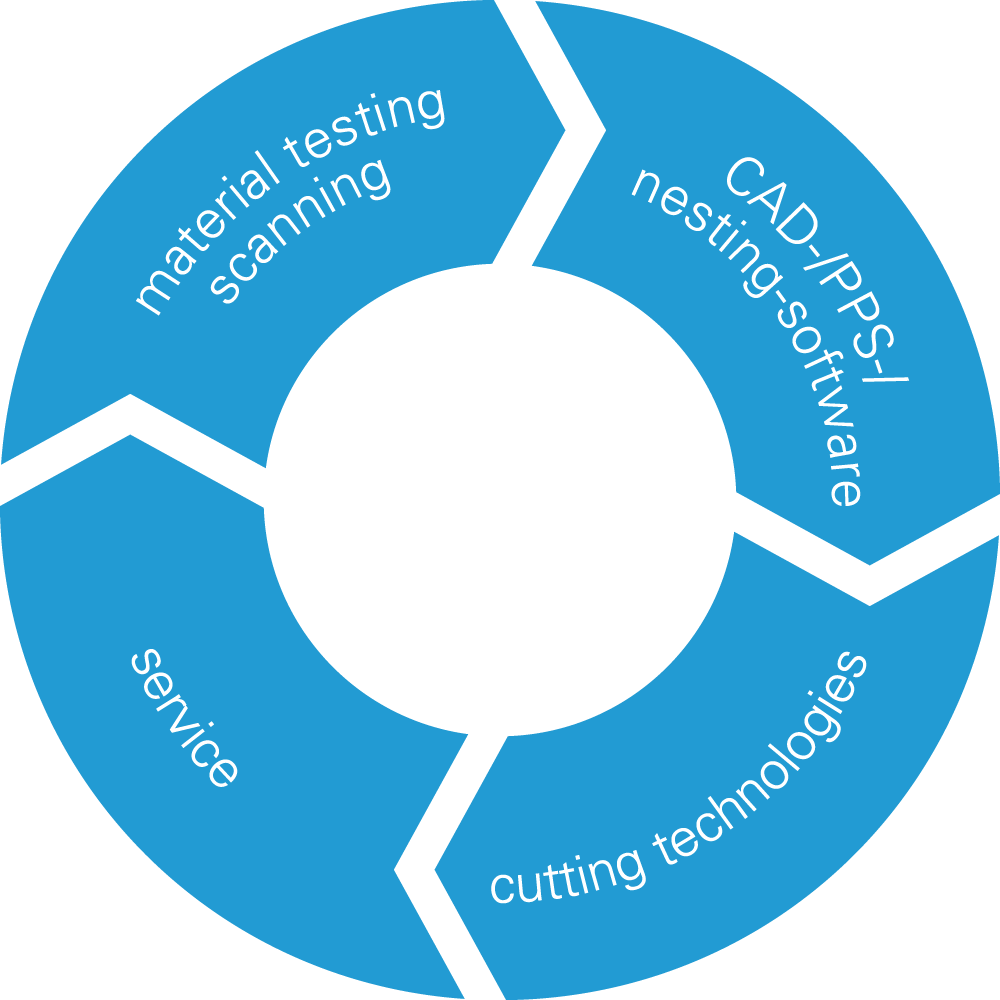

Using our engineering expertise, we construct individual waterjet and CNC cutting systems with high-quality components from renowned, reputable suppliers. In this connection we focus on modular cutting solutions for leather, fabrics, technical textiles and industrial materials for all industries. We cut (almost) everything. As part of the entire package you also receive the appropriate Software programs – which are modular on all process levels – straightforward and simple.

we think in cutting solutions.

The modular structure of our systems enables individual adjustment to your special challenges. Processes are separated due to the modular system structure, facilitating the highest level of flexibility. We construct your special system to suit your requirements.

In combination with our self-developed software applications for control, nesting and monitoring, you always receive solutions based on state-of-the-art technology. This is guaranteed by our in-house team of developers - all bright minds with a passion for technology.

Long-standing partnerships with renowned universities and associations ensure that as a medium-sized, family business we are also always one decisive step ahead in terms of technology, organisation and concepts. We are extremely proud of this - and will remain so in future.

Cutting

with water or blades?

(Pure) waterjet cutter or CNC cutter – a comparison of these cutting systems reveals that both have advantages and disadvantages. As always, which system is more appropriate depends on a number of factors. In this case - which material you would like to cut!

- Waterjet cutters are precise and can be used with the smallest of diameters

- CNC cutters are used specially for textiles and are therefore restricted in areas in which they can be used

For over 25 years expert has been constructing machines with waterjet technology for the cutting of a wide variety of flexible materials. Leather and a broad range of technical textiles can be cut flawlessly and at high speed. The fine waterjet is thinner than human hair when it cuts through the material at extremely high speed. The cut edges remain dry and do not deform thermally, as with laser cutters.

We recommend waterjet cutters, but we also offer high quality CNC cutters.

![]()

Advantages of the

waterjet cutter

- High speed and cutting precision

- No mechanical shifts of the material on the table

- Flexibility in choice of material and pattern contours

- Wear-resistant cutting base

- Minimal water consumption

- Less frequent tool changes

![]()

Strenghts of the CNC cutter

at a glance

- High cutting speed of up to 90 m/min

- Repeatability +/- 0.25 mm

- User-friendly, easily exchangeable cutting tools

- Cutting table with conveyor belt; accessible on 3 sides

Modular software from the same systems house.

expert software programs – further developed in our own systems house for 25 years – by experts for users. We are continually working on further development of our software programs.

Our aim is make your cutting processes more efficiently through automation using our in-house developed algorithms. You always retain your valuable data. Customer-specific program adaptations are a matter of course at expert. You get exactly what you need. Nothing more - but also nothing less.

- expert CAD software – quickly convert and easily digitise all patterns

- expert Nesting software – (fully) automated optimal nesting of patterns

- expert PPS software – intelligent planning and goal-oriented control of the production workflow