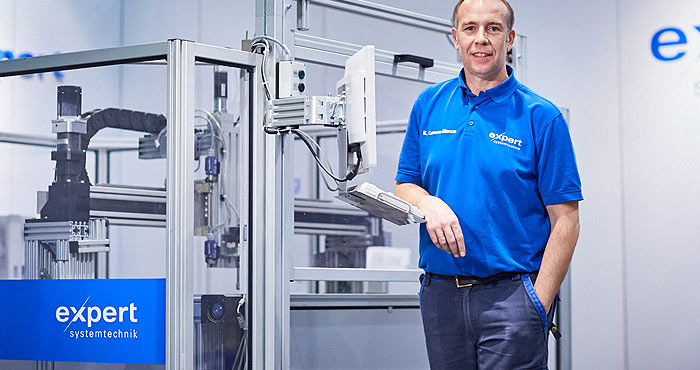

Special machine construction - individual development of the precisely fitting machine

Special machine construction is not a standard.

How true. Find a tailor-made solution for your cutting processes.

We build your machine modularly or design partial or complete processes in special machine construction. With more than 25 years of experience.

- One or two table solution

- Two axes (X-Y axis at 90° angle) or three axes (several layers? Z-axis for additional height adjustment)

- One or two cutting heads (up to 50% capacity difference)

- One or two cutting bridges (up to 40% reduction in cutting time)

- Steel honeycomb, felt underlay or wire belt

- With or without print head

- With or without milling unit

- With or without gluing station

- With or without labeller

- With or without unwinder

we think in cutting solutions.

![]()

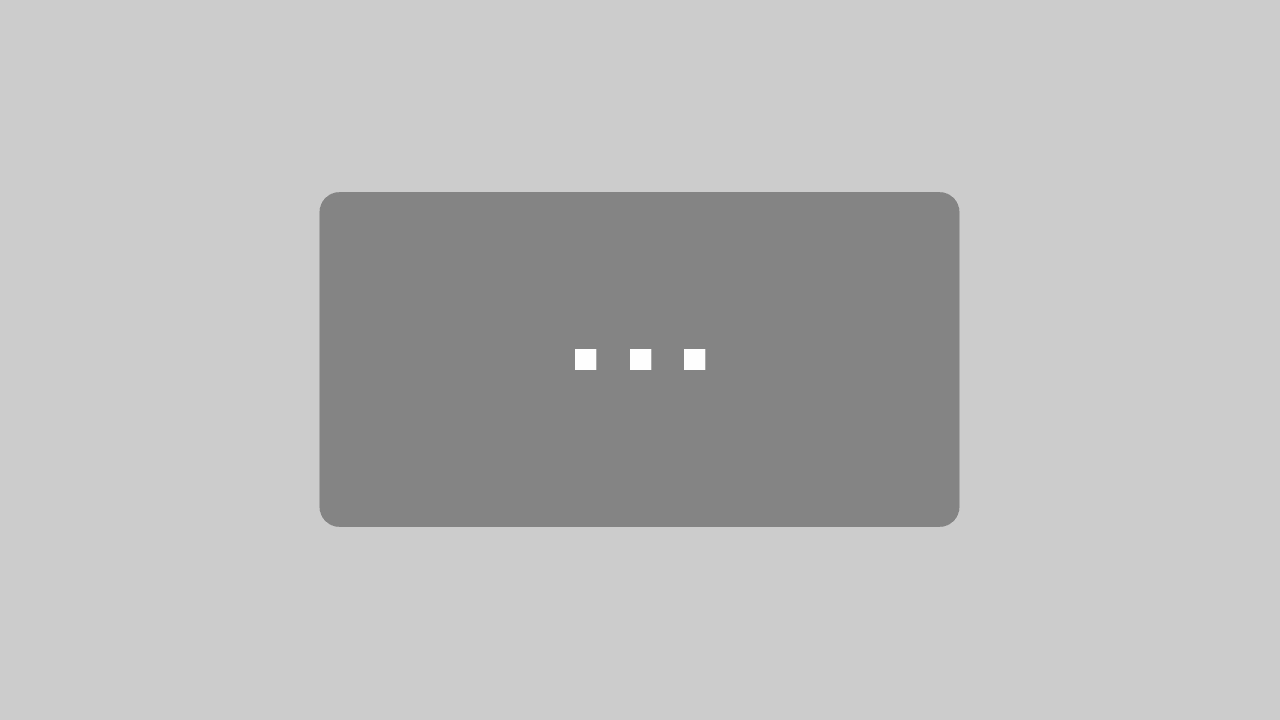

Example for a customer specified solution for cutting glass fibre mats

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Example of a customer-specific machine for cutting & printing in one machine

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Example for a customer specified solution for cutting polystyrene

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

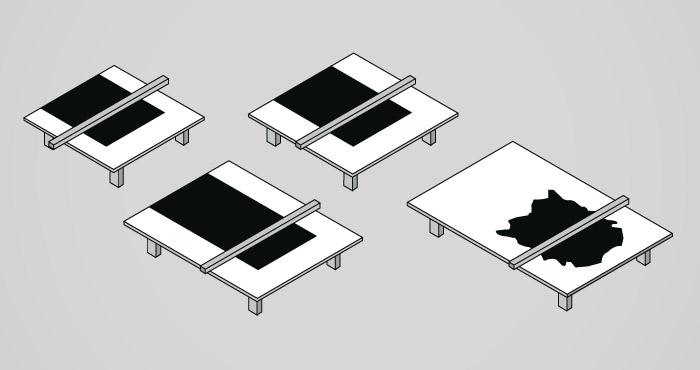

Table solution

1 or 2 table solutions

- 1 table solution

- 2 table solution

- Table top is a special steel honeycomb (durable, enables “dry” cutting).

- Capacity expansion

- Changing table principle

Z-axis

Z-axis in addition to X- and Y-axes

- Different materials require different heights

- Heights of up to 200mm

- Electronically adjustable

- Height control through material database

- Short set-up times

- Fewer user mistakes

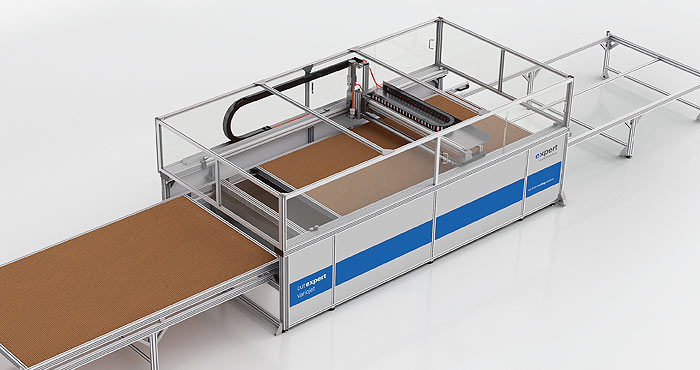

2nd cutting head

2nd additional cutting head

- Capacity increase due to use of 2nd cutting head on a bridge

- And increase up to 50%