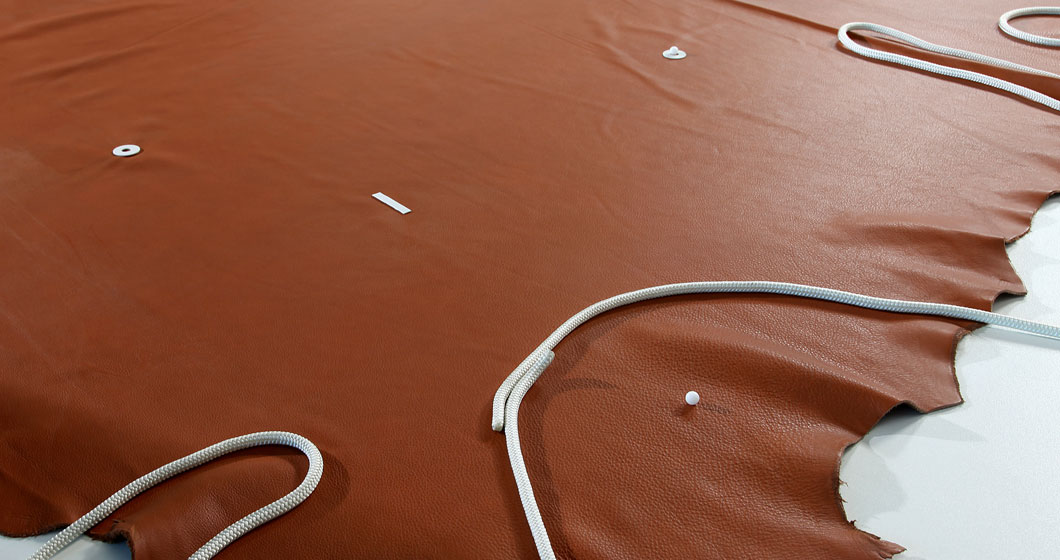

Quality inspection – recognising flaws in incoming goods

Significantly reduce material waste of hides. The recipe for success is fast and reliable recognition and documentation of quality zones and points of flaws.

You can reliably identify and classify hides before cutting but the method can also be used for the reverse process - when, after cutting, the shaped pieces are compared with the digitally recorded pattern data.

we think in cutting solutions.

![]()

2 different scanning methods for reliable leather identification

expert systemtechnik provides you with three different methods which can be used for optimal identification of your hides depending on the quantity:

- automated & CAD-controlled

- static

You can choose whether to have your hides checked by means of your quality assurance, CAD-controlled or our automated imperfection recognition.

More transparency during leather processing thanks to efficient data management

The expert scan-Software gives you complete transparency at the incoming goods stage and during further processing of the hides in your company. The incoming goods control reveals potential material savings and provides important key figures for your purchasing and cutting. Exactly what you need for transparent and efficient management of your leather stock.

Combination with other cutting systems is possible

It makes sense for processing to be comprised of scanning-nesting-cutting. The expert preliminary scanning equipment can, however, also easily be connected to various cutting machines from other manufacturers (e.g. Gerber, Lectra, Zünd). Our open interfaces make this possible – provided that the manufacturer allows this connection. This enables you to increase the efficiency of your cutting process without having to replace the entire cutting system.

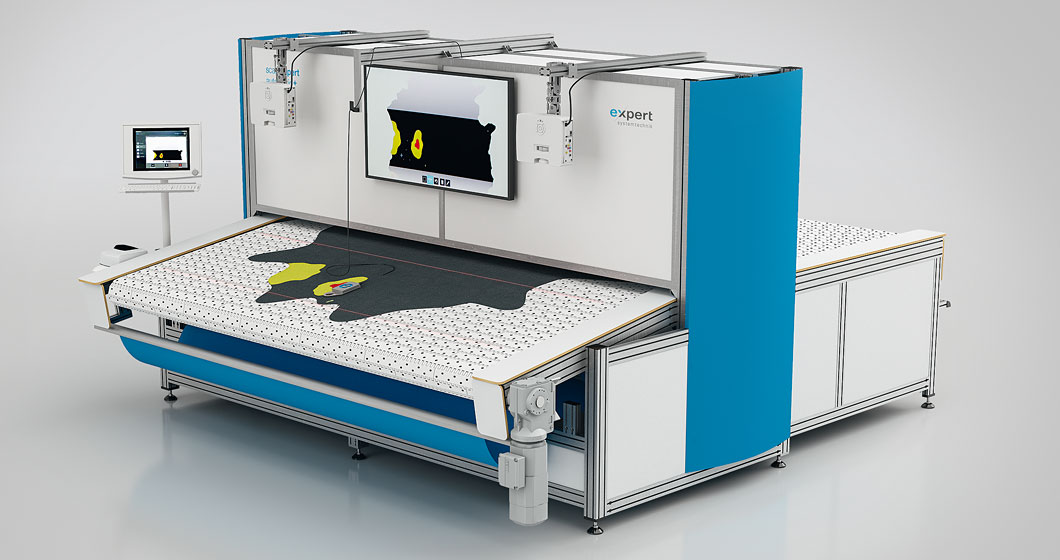

scan expert automatic+

Application area: Processing leather

Key module in incoming goods control and quality inspection for accurate registration of hides, hide imperfections, quality zones and other data – fully automated through AI.

- Automatic recognition within seconds of hide size, holes and markings by a high-definition camera

- Digitising of all quality zones by an employee using a digitiser cursor in accordance with company quality standards

- Fields previously marked (e.g. using chalk) are recorded by the camera during the scanning process

The key module in the expert system for complete incoming goods control and quality inspection of hides.

The data recorded provides absolute transparency concerning leather stocks. Quality and documentation and management of all important hide features such as size, quality zones, supplier name, colour, etc. in a database, for use in purchasing control.

Issue of a barcode for clear identification of each hide via barcode printer connected to the PC.

Possibility of connection to pre-select expert (automatically triggered nesting process for pre-selection of hides)

- Ergonomic hide transport system so that all parts of the hide are clearly visible at maximum arm's length

- User-friendly operation at the highest technical level

Conveyor: Belt in 2 high-contrast colours – for light and dark hides.

scan expert automatic

Application area: Upholstered furniture industry, automotive industry, aerospace industry, marine

Simple scanner for manual recognition of imperfections and recording of imperfections and qualities. Upgrade to scan expert automatic+ is possible.

Strengths:

- Transparent incoming goods control at all times

- Ergonomic hide transport system so that all parts of the hide are clearly visible at maximum arm's length

- User-friendly operation at the highest technical level

- Management of the recorded information in a database which can be used in purchasing control

Product features:

- Dimensions of digitising area: 3,000 mm x 3,000 mm

- Optimized scanning times due to leather transport via conveyor belt

- Automatic recognition within seconds of hide size, holes and markings by a high-definition camera

- Digitizing of all quality zones

- by an employee using a digitizer cursor in accordance with company quality standards or

- Fields previously marked (e.g. using chalk) are recorded by the camera during the scanning process

- Documentation in a database of all important hide features, such as size, quality zones, supplier name, colour, etc.

- Issue of a barcode for clear identification of each hide via barcode printer connected to the PC

- Possibility of connection to pre-select expert (automatically triggered nesting process for pre-selection of hides)

scan expert static table

Application area: Upholstered furniture industry, automotive industry, aerospace industry, marine

Strengths:

- Transparent incoming goods control at all times

- Ergonomic hide transport system so that all parts of the hide are clearly visible at maximum arm's length

- User-friendly operation at the highest technical level

- Management of the recorded information in a database which can be used in purchasing control

Product features:

- Dimensions of digitising area: 3,000 mm x 3,000 mm

- Optimised scanning times due to leather transport via conveyor belt

- Automatic recognition within seconds of hide size, holes and markings by a high-definition camera

- Digitising of all quality zones

- by an employee using a digitizer cursor in accordance with company quality standards or

- Fields previously marked (e.g. using chalk) are recorded by the camera during the scanning process

- Documentation in a database of all important hide features, such as size, quality zones, supplier name, colour, etc.

- Issue of a barcode for clear identification of each hide via barcode printer connected to the PC

- Possibility of connection to pre-select expert (automatically triggered nesting process for pre-selection of hides)