Waterjet cutter - High efficiency for flexible materials

Resource-saving waterjet cutters are sustainable. Get fit for the future.

expert Waterjet cutters cut flexible materials - leather, PU, PE and more...

In lightweight construction and modular design constructed standard solutions or customised special machines according to your requirements.

Water cutters safe time and money because they are highly efficient and user-friendly. Everything you could wish for.

By thinking differently, combining and connecting, we create practical solutions with real added value.

That's exactly how we develop and design waterjet cutters - actually all our machines, software and services

We act as an initiator and sparring partner for all kinds of technical problems. If we can’t find a solution, there isn’t one.

we think in cutting solutions.

![]()

Our satisfied customers include

- Automobile manufacturers and suppliers of exclusive brands

- Manufacturers of high-quality upholstered furniture

- Processor of orthopaedic shoe insoles

- Manufacturer of first-class shoes and bags

- Processors of, among other things, safety-relevant sealing materials

- Transport packaging for custom-fit solutions

Waterjet cutter cut a wide range of flexible materials

- Sheet products such as flexible plastics, synthetic materials, cardboard and corrugated cardboard, rubber, sealing materials, foams

- rolled products such as a variety of technical textiles like composites, glass fibre, but also foam

- leather hides or also only parts of hides

Precise, flexible and efficient cutting - and saving resources, these are the requirements that our customers can meet with expert machines.

Some machines have already been running for over 20 years!

Read now about the advantages of waterjet cutter in the pure waterjet cutting technology and our modular expandable waterjet cutting machines.

Cutting flexible material with Waterjet cutter from expert

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Waterjet cutting technology is appropriate for many types of flexible material: We are happy to check in advance whether or not your material can be cut using this eco-friendly waterjet cutting technology – at no additional cost to you, of course.

Send us a sample of your material with details of your requirements or a cutting file. We will do your cutting, no obligation. You will then get the cut material back from us – together with a report on our findings. This avoids any frustrating extra work for you.

Find out in advance if waterjet cutting technology is right for you – free of charge and without any obligation.

Cutting with water jet - in the imagination a dirty business, where metal, glass or and stone is cut with water and sand. Who does not know the pictures of the smallest watch movements, cut with water jet and abrasive materials, like sand?

That is abrasive water jet cutting, but we do not deal with that.

(Pure) waterjet cutting machines use the process in which fresh water cuts by compression alone, i.e. pressure. Clean and pure.

And this is how it works:

Water is forced at very high pressure, 3,800 bar - 6,000 bar, through a very fine and narrow nozzle. The resulting high speed (kinetic energy) accelerates the water to about 1,000 meters per second.

In other words, the combination of water forced through a small opening at high pressure produces a very fine jet that cuts the (flexible) material with very high energy with an accuracy of approx. +/- 0.1 mm.

In a nutshell, the difference between the two methods is the application:

Abrasive water jet for harder materials

&

Pure water jet for flexible, so called bending-flabby materials.

Cutting with waterjet - does the material get completely wet and have to dry for days?

Waterjet cutting technology is a very precise technology. The material becomes "wet" at the cutting edge through contact with the water. After cutting, the material is "lip wet". Within a very short time, the material dries completely without any change in the material!

A special feature of expert waterjet cutting machines is that they operate with extreme precision and cutting speed without changing the properties of the material to be cut. Numerous advantages compared with mechanical cutting such as:

- Minimal water consumption

- Less frequent tool changes

- Extremely wear-resistant cutting base

combined with minimal operating costs, make this technology cost-efficient and eco-friendly.

Advantages of (pure) waterjet cutting technology

- Precision

smallest cutting gap 0.08 mm | part accuracy +/- 0.1 mm | any shape can be contour cut (from 0.08 mm) - Flexibility

Faster material or geometry changes due to short set-up times - Efficient material savings

The water jet does not require any gaps (buffers) between the parts. Material savings potential (sustainability) - Combined work steps

The ideal solution is to combine the waterjet and a further manufacturing step (milling) in one process - Extended application possibilities

The angle cut is another option. For example when processing foam plastics

Benefits

- Cut the most difficult contours

- Use maximum material

- Higher productivity through high cutting speed (capacity)

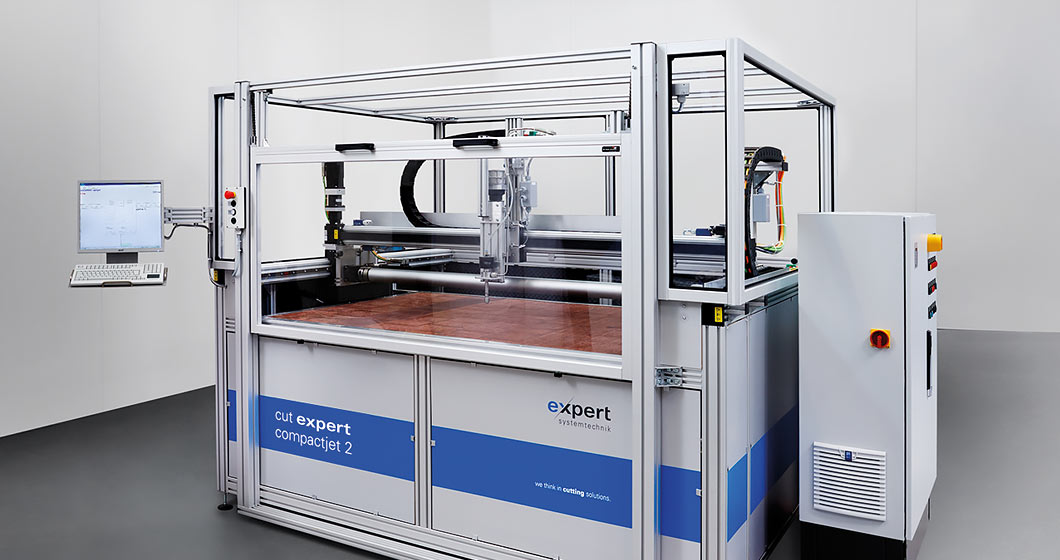

cut expert compactjet 2 - the cost-effective complete waterjet cutter

Application area:

Multi-functional CAM cutting system with 1 cutting bridge and 1 cutting head

Cost-effective cutter for small series, prototypes and model creation

Strengths:

- cost-effective entry-level solution

- field of application: cutting of foam, plastic, technical textiles and others

- high cutting speed up to 70 m/min

- extremely low water consumption of approx. 0.2 l/min

- highest precision in cutting

- no vacuum necessary

- easy cleaning

- modular design allows easy expansion for increased capacity requirements

Product features:

- Cutting surface: cuting area in different sizes: S, M, L and XL

- 1 cutting table, 1 cutting bridge and 1 cutting head

cut expert variojet - the waterjet cutter with extendable table

Application area: Textiles, technical materials

Multi-functional CAM cutting system with 1 cutting bridge and 1 cutting head

Strengths:

- High cutting speed of up to 70 m/min

- Repeatability of +/- 0.2 mm

- Extremely low water consumption of approx. 0.2 l/min

- Precise cutting

- No geometric restrictions for holes, contours, etc.

- no vacuum required

- Environmentally-friendly waterjet technology

Product features:

- Cutting surface: 1,800 mm x 3,000 mm; other sizes possible at the customer's request

- Suitable for both sheet and rolled material

- Basic configuration:

- one cutting head, expandable to two parallel-driven cutting heads

- one moveable cutting table, expandable by an additional cutting table

What our customers say - Material glass fiber

"The key to the decision to buy a waterjet cutter was an extensive testing phase at expert to push the demonstration machine to the limit. This test was carried out by expert with us free of charge.

The prejudices against waterjet cutting technology, possible residual moisture and thus possible mold formation were completely dispelled. Cut material (glass fiber mats) was taken away for testing and sealed in cardboard boxes at the company for weeks. No mold formed even after several weeks.

We quickly decided to buy a water jet cutter. The cutter has been running permanently ever since.

expert was always available and is very helpful; although no service and maintenance contract was signed. The service is very good, also the spare parts supply and accessibility."

cut expert conveyor - the waterjet cutter with conveyor

Application area: Rolls of textiles and technical materials

Multi-functional CAM cutting system as a conveyor model, divided into feed zone, cutting zone and pick-up zone

Strengths:

- Waterjet cutting with wire conveyor: minimal spattering and wear-free

- Repeatability of +/- 0.2 mm

- High cutting speed

- Environmentally-friendly waterjet technology

Product features:

- Cutting surface: 1,800 mm x 3,000 mm; other sizes possible at the customer's request

- Cutting table with stainless steel belt for continuous cutting

- Basic configuration:

- one cutting head, expandable to two parallel-driven cutting heads

- one moveable cutting table, expandable by an additional cutting table

- Jet catcher to reduce spattering and moisture

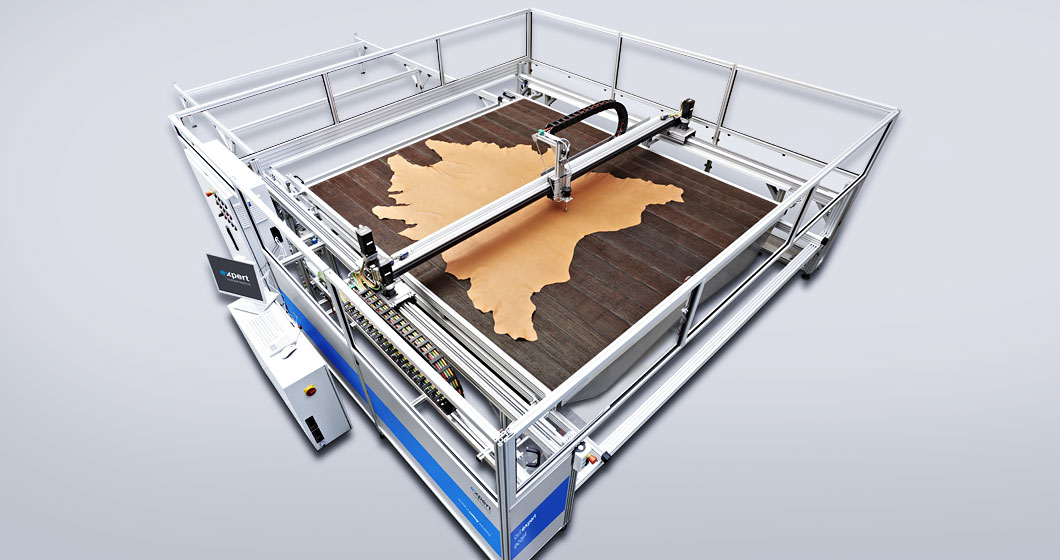

cut expert ecojet - the waterjet cutter for leather hides

Application area: Leather

Multi-functional CAM cutting system with 1 cutting bridge and 1 cutting head

Strengths:

- High cutting speed of up to 70 m/min

- Repeatability of +/- 0.2 mm

- Extremely low water consumption of approx. 0.2 l/min

- Precise cutting

- No geometric restrictions for holes, contours, etc.

- No vacuum required

- Environmentally-friendly waterjet technology

Product features:

- Cutting surface: 2,900 mm x 2,700 mm

- Basic configuration:

- one cutting table, expandable by an additional cutting table

- one cutting head

- Cutting speed: 70 m/min

- Cutting performance of 70 – 90 hides per 8-hour shift, depending on the type and complexity of the patterns

cut expert doublejet - the double waterjet cutter for leather hides

Application area: Leather

Multi-functional CAM cutting system with 2 cutting bridges and 2 cutting heads

Strengths:

- Suitable for handling large quantities at high capacity

- Very short cutting times thanks to high cutting speed of up to 140 m/min

- Repeatability of +/- 0.2 mm

- Extremely low water consumption of approx. 0.2 l/min

- Precise cutting

- No geometric restrictions for holes, contours, etc.

- No vacuum required

- Environmentally-friendly waterjet technology

Product features:

- Cutting surface: 2,900 mm x 2,800 mm per cutting table

- Basic configuration: two static tables and two moveable cutting bridges, both available for the entire cutting surface

- Cutting speed: 70 m/min

- Extremely short cutting times thanks to simultaneous operation of two cutting bridges

- For a cutting performance of 120 – 240 hides per eight-hour shift, depending on the type and complexity of the patterns

Waterjet cutting technology is just one of many cutting techniques.

It is, however, an extremely interesting option in comparison with laser, blade or the old craft of punching technology. It is environmentally friendly, relatively easy to operate and is suitable for cutting a variety of flexible materials.

Speak to our experts. Send us your material. We will carry out a cutting test for you, free of charge.